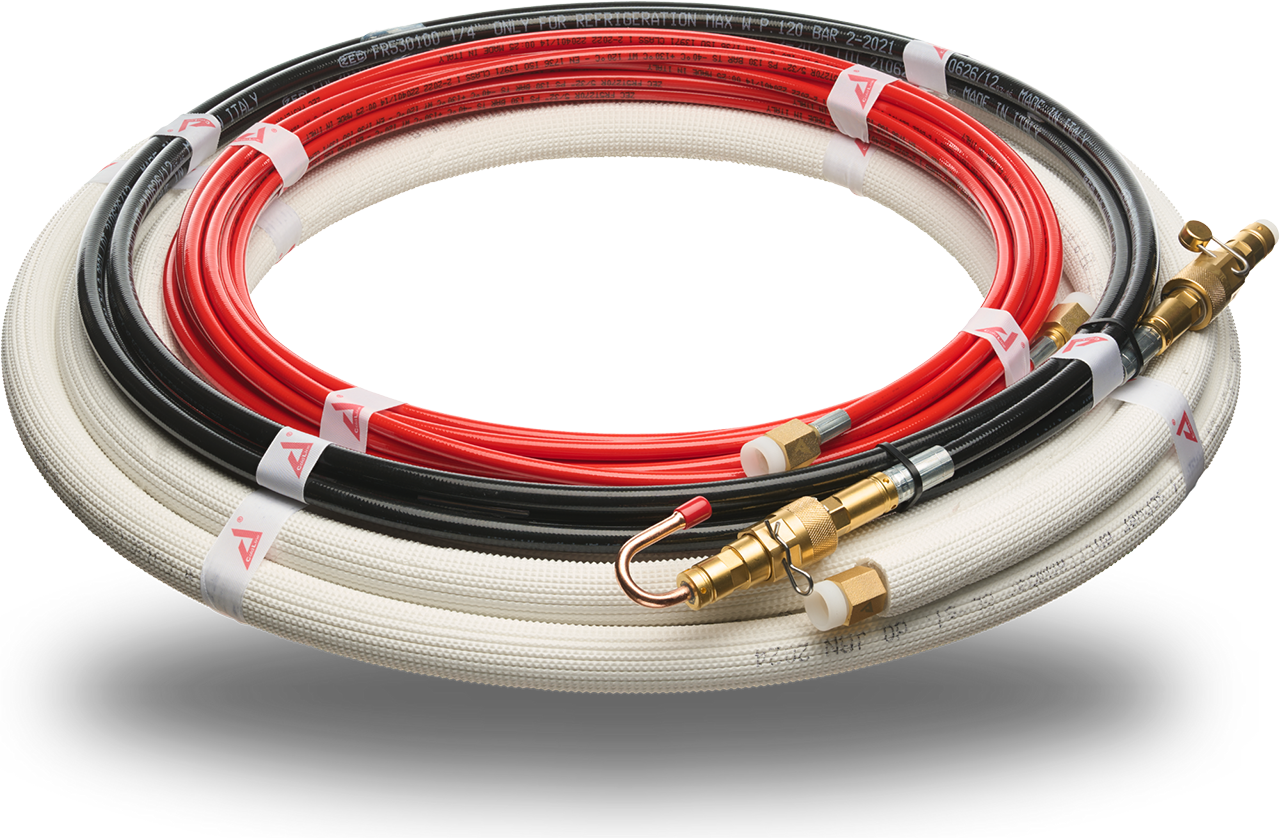

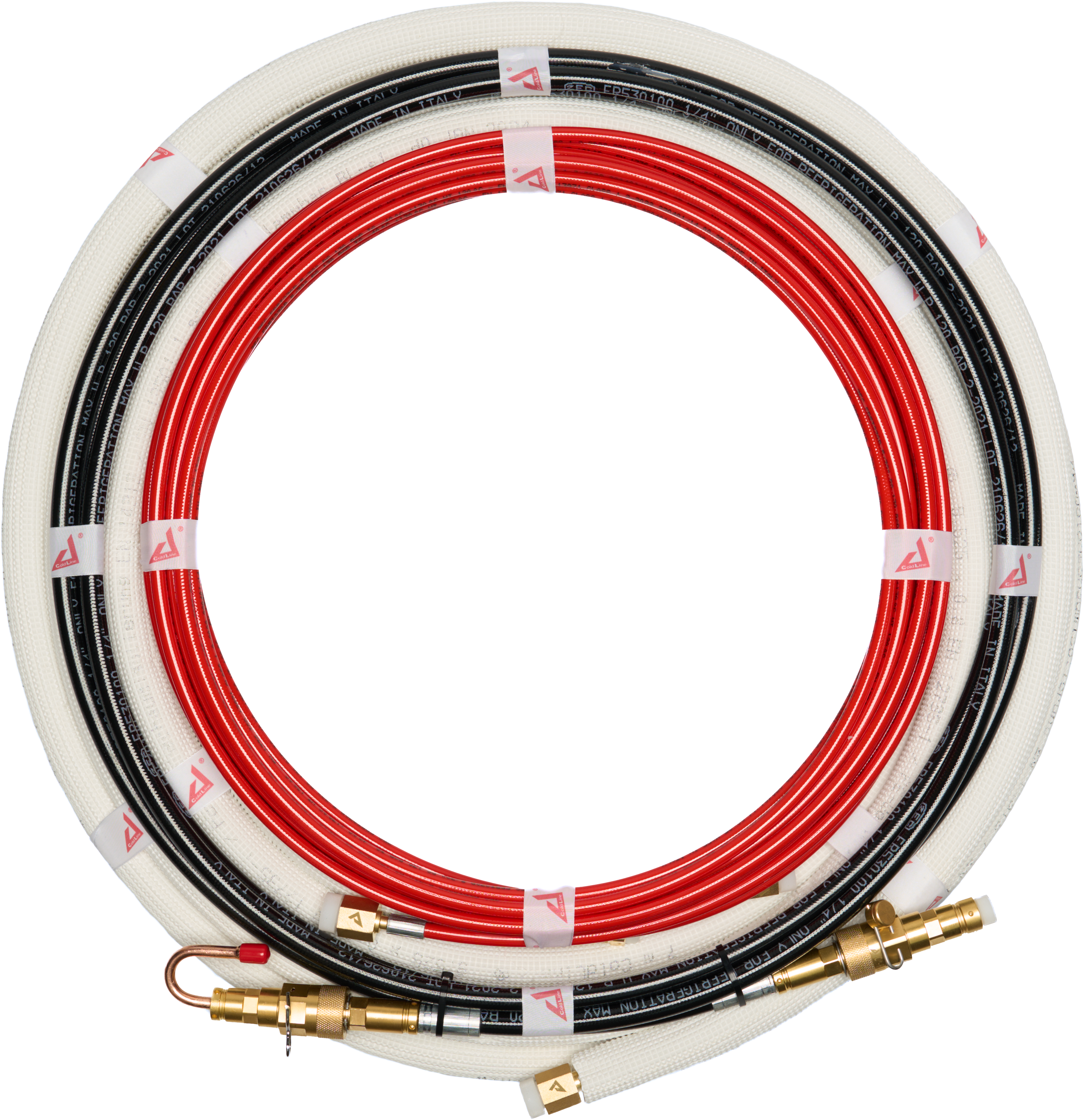

Thermoplastic refrigerant hoses with companion valves

Reliable, Durable, and Customizable – with customizable lengths and the latest valve generations, we offer top-tier performance and reliability.

Send us a message with your

individual requirements!

For efficient and secure HVAC and refrigeration systems

-

Full Compliance

Our hoses meet the standards of EN 1736:2009-02 for refrigerating systems, ensuring their durability, design, and installation requirements are fully met.

-

Galvanic Isolation

Full galvanic isolation of components and units.

-

Low Permeability

Up to 76 % lower permeability than the best class (EN 1736).

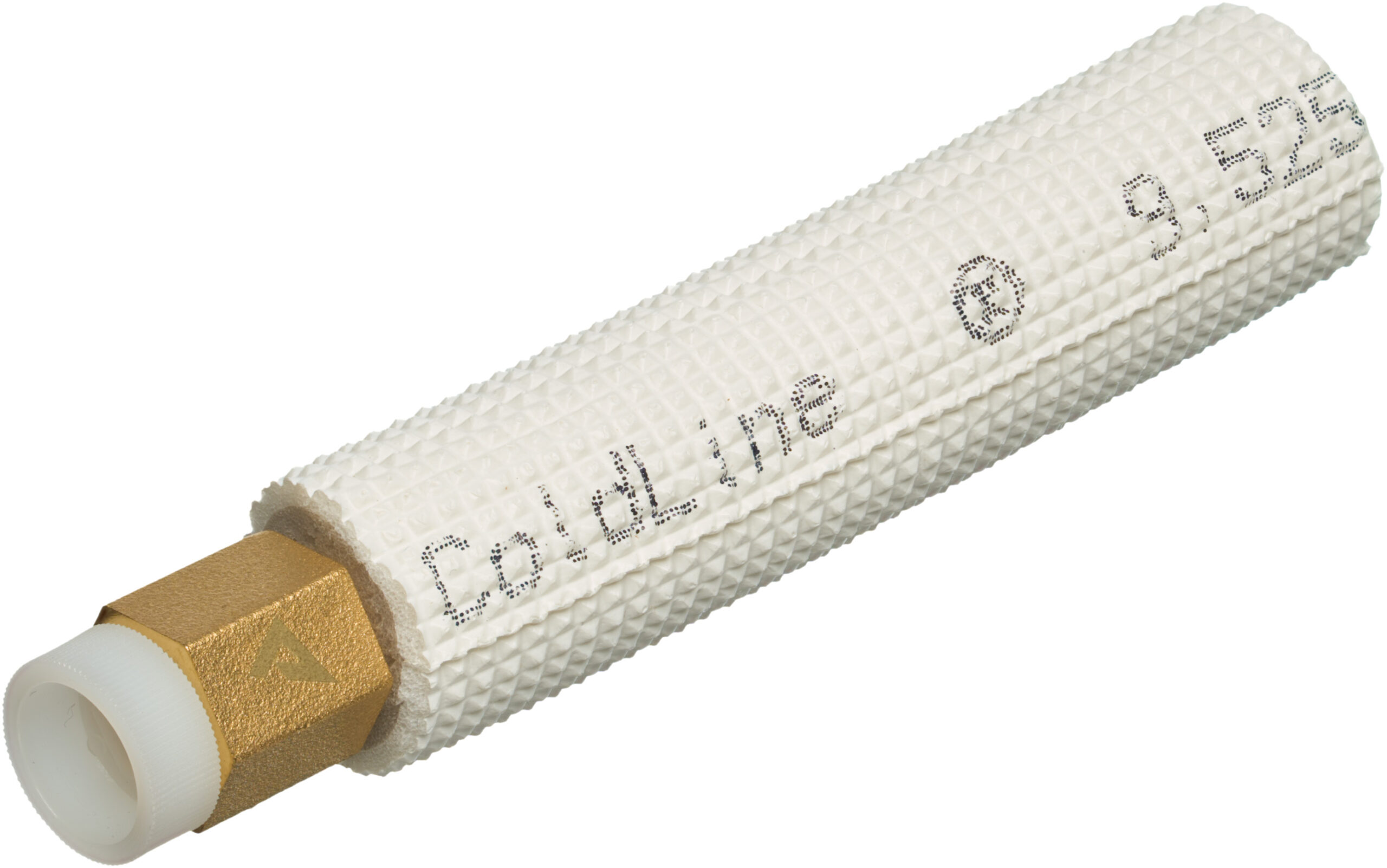

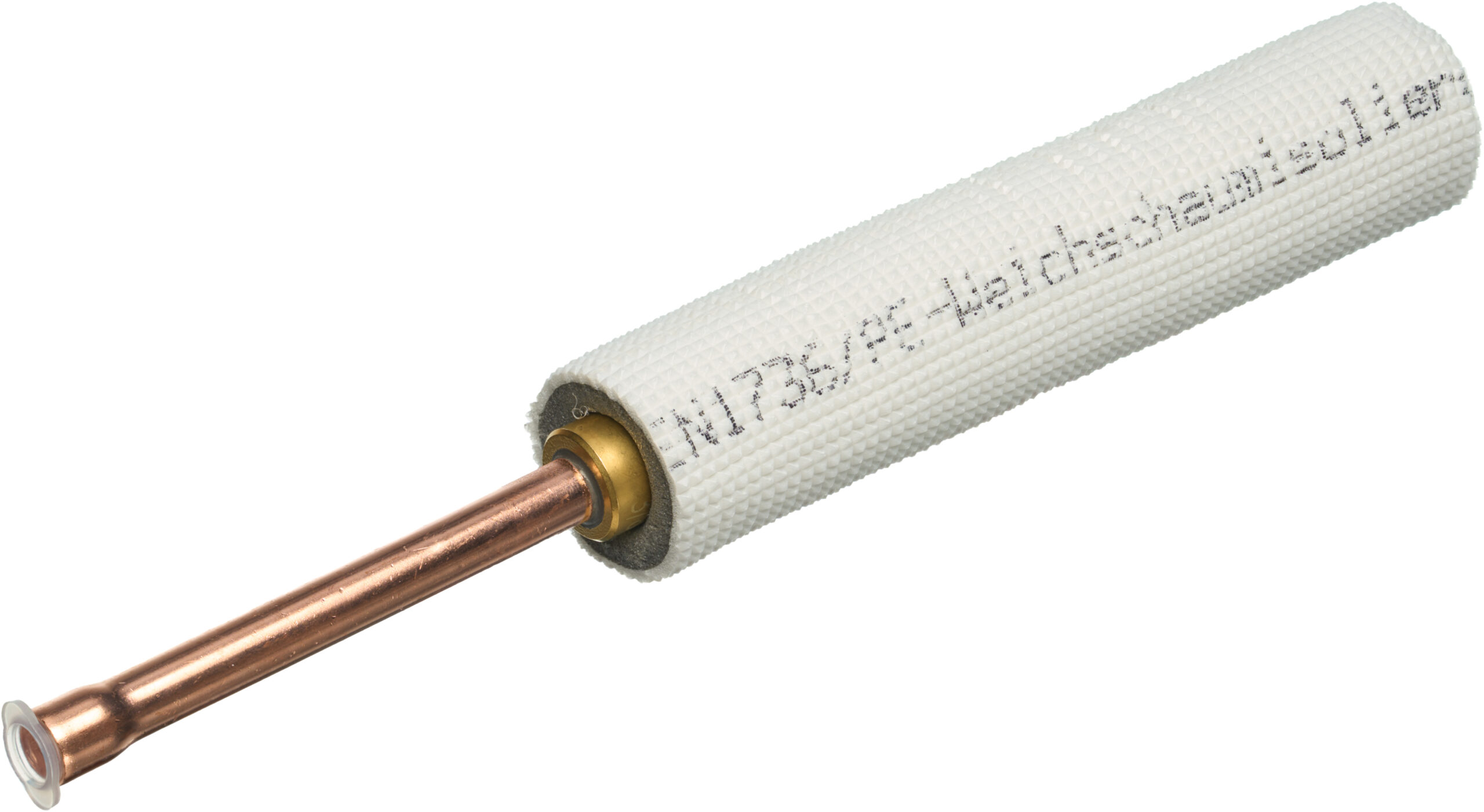

Stop valve

for R290

Stop valve

for HFC

Flare connectors

Solder connectors

DN2 – DN17

Customized lengths up to 20 m

Evacuated or prefilled

The flexible lines with two stop valves are evacuated or, if required, are supplied prefilled with the appropriate refrigerant.

Technical-constructive features

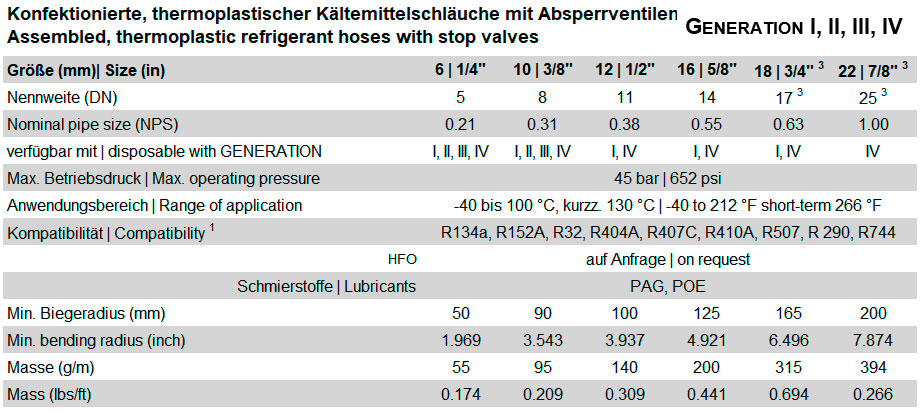

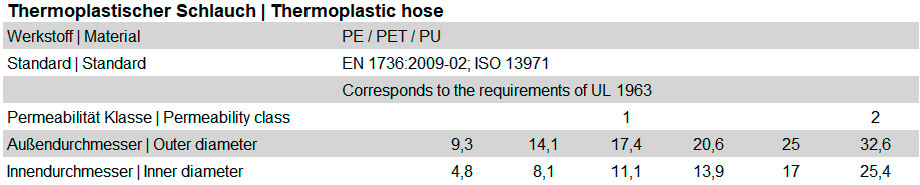

The polyethylene-based hoses meet the requirements of DIN EN 378-2 item 5.3.1.4 d) Plastics. The needs of EN 1736:2009-02 Refrigerating systems and heat pumps – Flexible pipe fittings, vibration absorbers, expansion joints and non-metallic hoses – Requirements, design and installation are fully met. In addition, the permeability of the best class defined in the standard is at least maintained.

The inner core of the hoses is made of elastomer polyamide. The reinforcement braid made of high-strength polyester yarn (PET) and the micro-perforated anti-abrasion polyurethane cover (PU) gives the hose high compressive strength and resistance to surface abrasion.

The insulation is encased in a challenging, UV-stable shell. Dimensions and tolerances comply with EN 14313:2015, Tables 1 and 2. The fire behavior corresponds to Euroclass, BL-s1, d0 (flame retardant), classified according to EN 13501-1.

Areas of application

Thermoplastic refrigerant lines have a larger bending radius than comparable hoses made of elastomeric material but have much lower permeabilities. They are mainly chosen when the tightness of the installations is a priority and the larger radii can be tolerated:

- for safe, simple and time-saving relocation of refrigeration and air-conditioning systems and heat pumps

- particularly suitable for temporary installations where fixed lines installations are unsuitable

Our catalog

The catalog to browse, save or print contains further technical data and specifications for our products.

For the sake of the environment, we refrain from sending the catalogs in paper form and ask for your understanding.

About us

Cold Solutions was founded as a distributor of companion valves and fabricated copper refrigerant lines, especially for split air conditioning systems, at the Port of Hamburg.

Today, Cold Solutions sees itself as a functional specialist for the development, design and manufacture of innovative companion valves as well as assembled copper refrigerant lines and flexible refrigerant hoses for refrigeration, air conditioning and heat pump technology.

Our in-house developed, self-closing companion valves, especially of generations I(A), II, III and IV, are characterized by outstanding tightness and excellent reliability.