Generation I

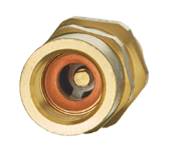

Specially designed for split air conditioners and heat pumps, repeated coupling and decoupling of the stop valves is expected only sporadically (see technical data – up to 75 times).

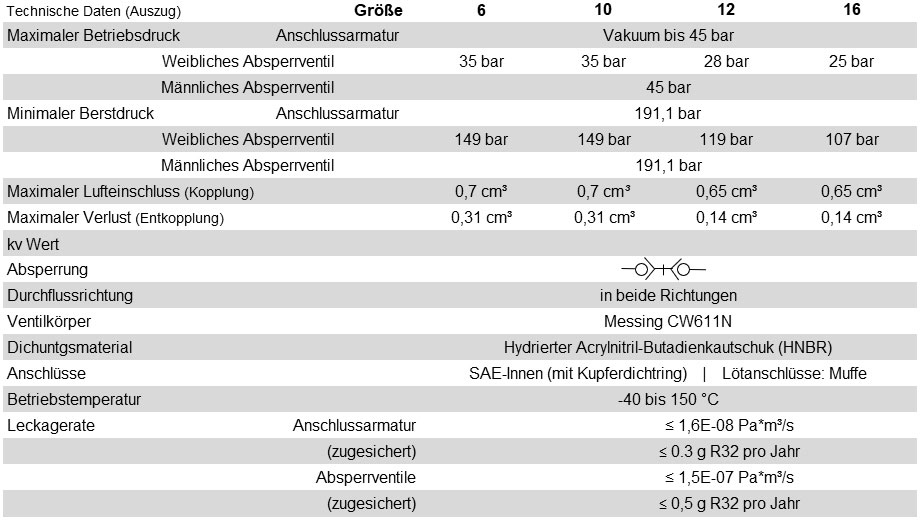

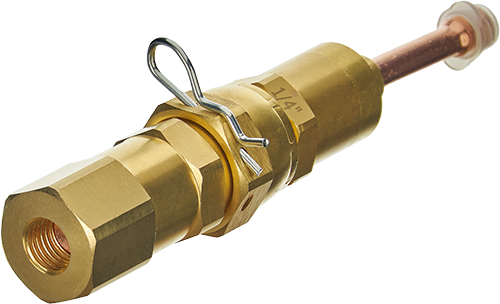

The unique design allows the stop valves to be expertly coupled without using torque or other special tools.

Repeated coupling and decoupling without evacuation/refilling of components and lengthy interruptions in refrigeration and air conditioning systems operation.

Industrially manufactured (flared) connections eliminate errors during assembly and ensure high reliability and minimal leakage rates.

Reduce the effort required in the event of a warranty or guarantee claim or when replacing components.

Savings in time and technical equipment during the assembly of new plants and maintenance.

Preventing the often complete loss of refrigerant in the event of improper disassembly or maintenance by non-certified persons or companies (see Regulation (EU) No. 517/2014).

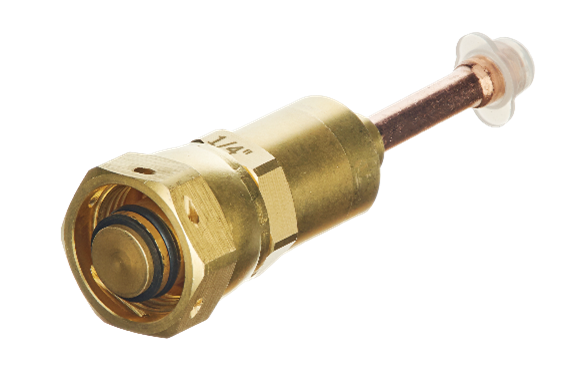

European Standard 378 for refrigeration systems and heat pumps requires, in part 2, a sufficient number of shut-off valves to minimize the risk of refrigerant loss. Generation I connection valves each consist of two matching, self-closing shut-off valves. Their use reliably prevents the escape of refrigerants, especially during maintenance.

Generation I connection fittings meet the requirements of Regulation (EU) No. 517/2014 on fluorinated greenhouse gases concerning maximum permissible leakage rates of up to 70 couplings and decouplings.

Seals made of HNBR ensure a wide temperature application range and good chemical resistance to the refrigerants and refrigerating machine oils mentioned in the technical specifications.

Male stop valves with SAE female thread for flared connections with pressed-in copper sealing ring and female stop valves with soldering sleeves for inch-diameter pipes.