Elastomeric refrigerant hoses with solder and flare connections

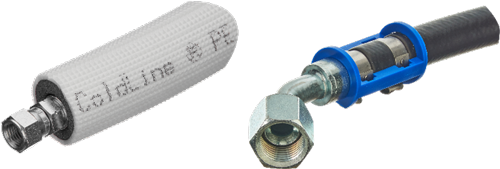

with solder connections

with solder connections and flare connections with SAE union nuts

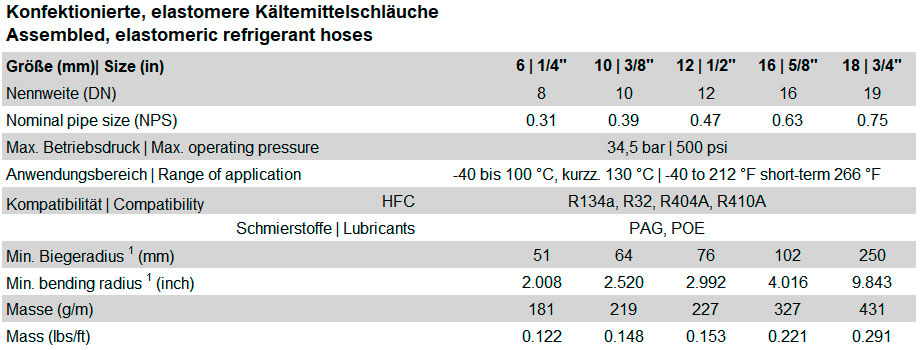

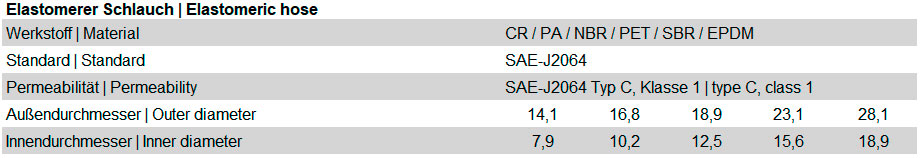

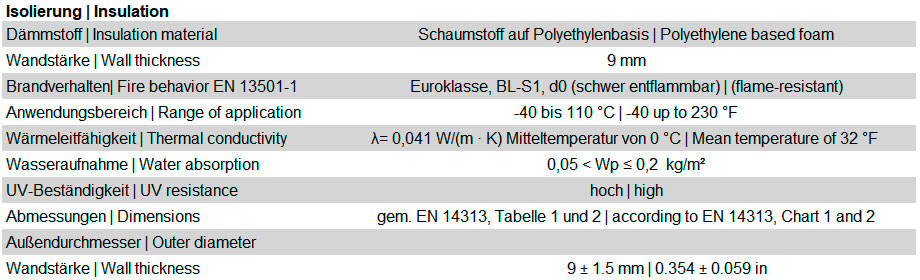

The elastomer hoses of nominal sizes 1/4″ to 5/8″ are manufactured in customized lengths up to 20 m.

Technical-constructive features

The refrigerant hoses [with closed-cell insulation] based on polyethylene meet the requirements of DIN EN 378-2 item 5.3.1.4 e) Elastomers. In addition, the hoses are manufactured according to SAE-J3062 and meet the needs of the SAE-J2064 standard.

The barrier layer is made of polyamide and the printing substrate of polyester yarn (PET). The sheathing is made of abrasion and weather-resistant synthetic rubber (EPDM). A total of 7 layers ensure functionality, permeability, and moisture ingress rate. The cables were tested according to DIN EN 372-2 point 5.3.2.

The insulation is encased in a challenging, UV-stable shell. Dimensions and tolerances comply with EN 14313:2015, Tables 1 and 2. The fire behavior corresponds to Euroclass, BL-s1, d0 (flame retardant), classified according to EN 13501-1.

Elastomer refrigerant lines have a smaller bending radius than comparable hoses made of thermoplastic material and are more flexible but have a higher permeability. They are mainly chosen when flexibility and small bending radii are the priority: