Thermoplastic refrigerant hoses with solder and flare connections

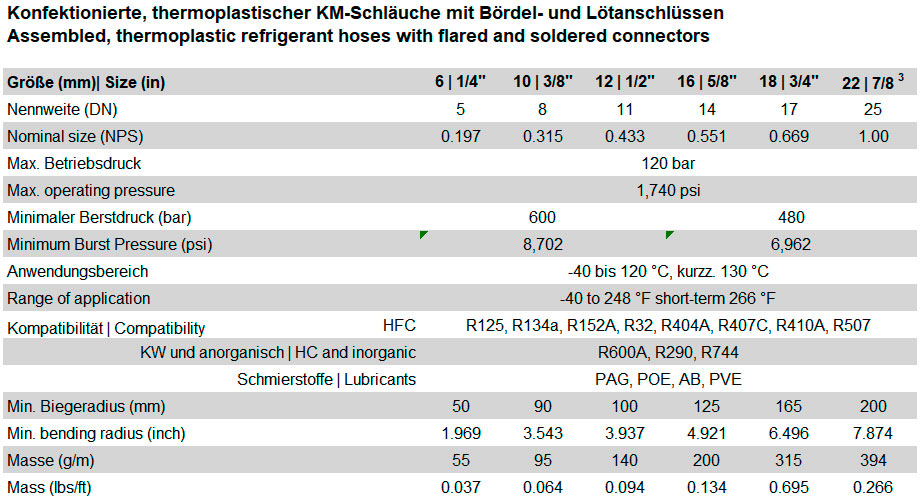

The thermoplastic hoses of nominal sizes 1/4″ to 3/4″ are manufactured in customized lengths up to 20 m.

Technical-constructive features:

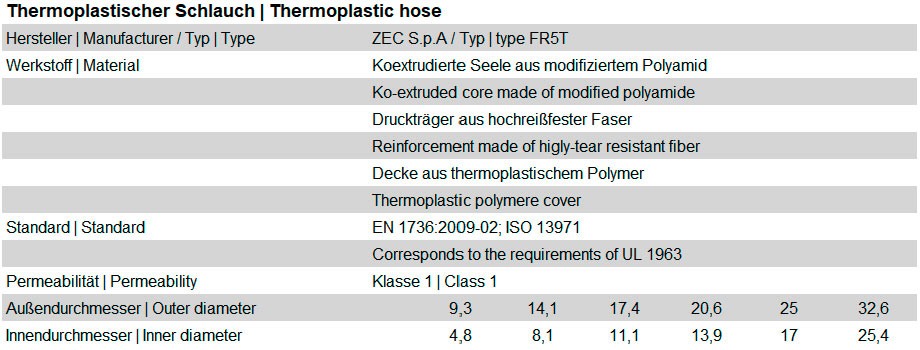

The refrigerant hoses [with closed-cell insulation] on polyethylene basis meet the requirements of DIN EN 378-2 points 5.3.1.4 d) Plastics. The needs of EN 1736:2009-02 Refrigerating systems and heat pumps – Flexible pipe fittings, vibration absorbers, expansion joints and non-metallic hoses – Requirements, design and installation are fully met. The permeability of the best class defined in the standard is at least maintained.

The inner core of the hoses is made of elastomer polyamide. The reinforcement braid made of high-strength polyester yarn (PET) and the micro-perforated anti-abrasion polyurethane cover (PU) gives the hose high compressive strength and resistance to surface abrasion.

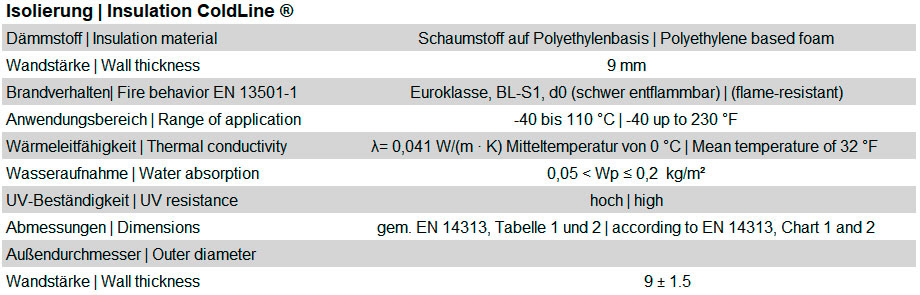

The insulation is encased in a challenging, UV-stable shell. Dimensions and tolerances comply with EN 14313:2015, Tables 1 and 2. The fire behavior corresponds to Euroclass, BL-s1, d0 (flame retardant), classified according to EN 13501-1.

Thermoplastic refrigerant lines have a larger bending radius than comparable hoses made of elastomeric material but have much lower permeabilities.

Another advantage over elastomer hoses is their excellent media compatibility with refrigerants and refrigerator oils.

Thermoplastic hoses without companion valves are mainly used when a permanent and long-term connection of the components is expected, and professional equipment can be provided at the installation site without high costs.